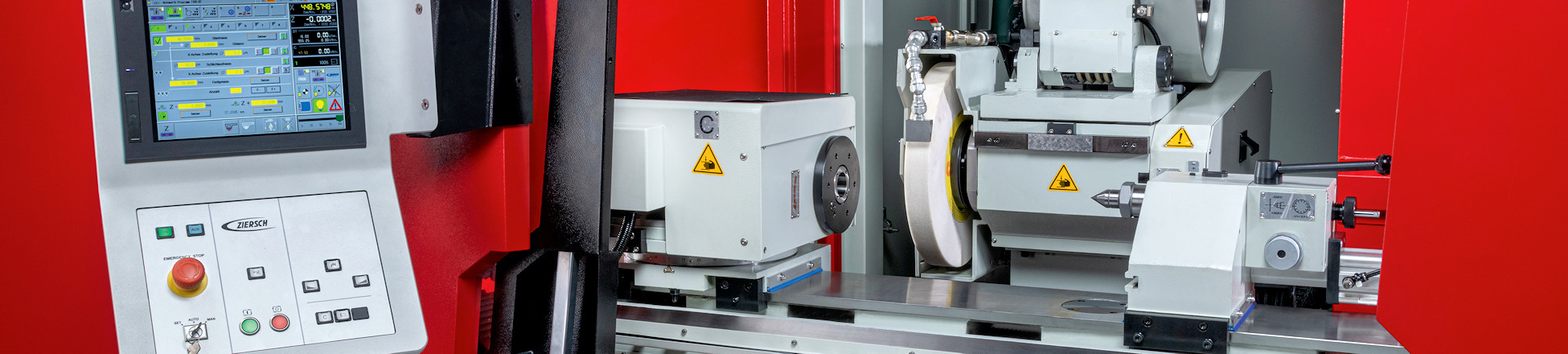

Cylindrical grinding machines ZR-SERIES

Control

- User-friendly Z-Control with high comfort

- Manual grinding function with open door at reduced speeds

- Fully automatic grinding cycle with dressing cycles

- Grinding cycles: cylindrical grinding and plunge grinding

- Grinding modes: roughing, finishing and spark out

- Dressing cycles divided into roughing and finishing

- Automatic infeed with compensation of the dressing amount

- Night shutdown program

- Easy and intuitive operation through a large, user-friendly touchscreen

- Electronic handwheels, usable in the X- and Z-axis, switchable in four stages to 0,0001/0,001/0,01 and 0,1 mm

- Rigid cast iron machine components

- High machine weight for maximum rigidity

- Full enclosure of the machine with large service and maintenance doors; effective splash protection with excellent accessibility

- Preloaded precision linear guideways in the X-axis (Bosch Rexroth) for highest accuracy

- Excellent damping characteristics and high surface finish quality thanks to ground V-flat sliding guideways in the Z-axis

- Automatic central lubrication in the Z-axis (slideway oil) and in the X-axis (grease)

- Electromechanical drive of the X- and Z-axis

- Precise positioning using a direct measuring system on the X-axis (Heidenhain) and a rotary encoder on the Z-axis

- Continuously adjustable grinding spindle motor with constant cutting speed up to 35 m/s (optionally up to 50 m/s) over the entire range of use of the grinding wheel for the external cylindrical grinding (vconstant)

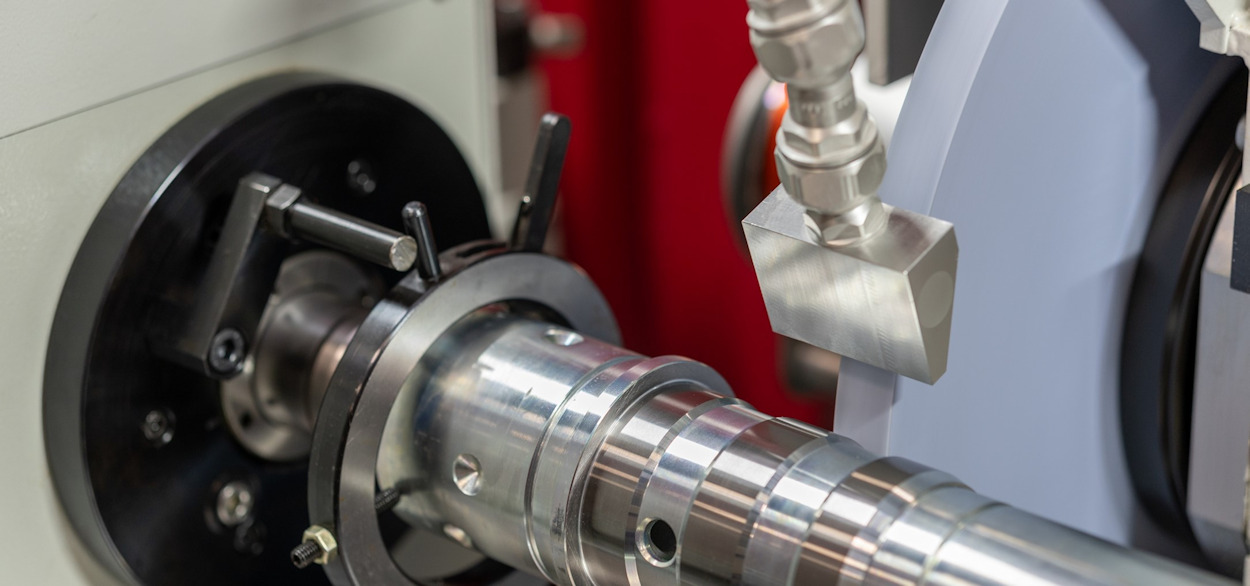

- Long service life due to an external cylindrical grinding spindle supported by 6 rolling bearings, grease-lubricated for life

- Optional: manually swiveling internal grinding attachment with continuously adjustable internal grinding spindle (ZR 600 & ZR 1000)

- Automatic switch from external to internal cylindrical grinding via B-axis (ZR 300)

- Maintenance-free belt filter system with integrated channel flushing incl. cleaning gun with hose and magnetic separator for pre-filtration