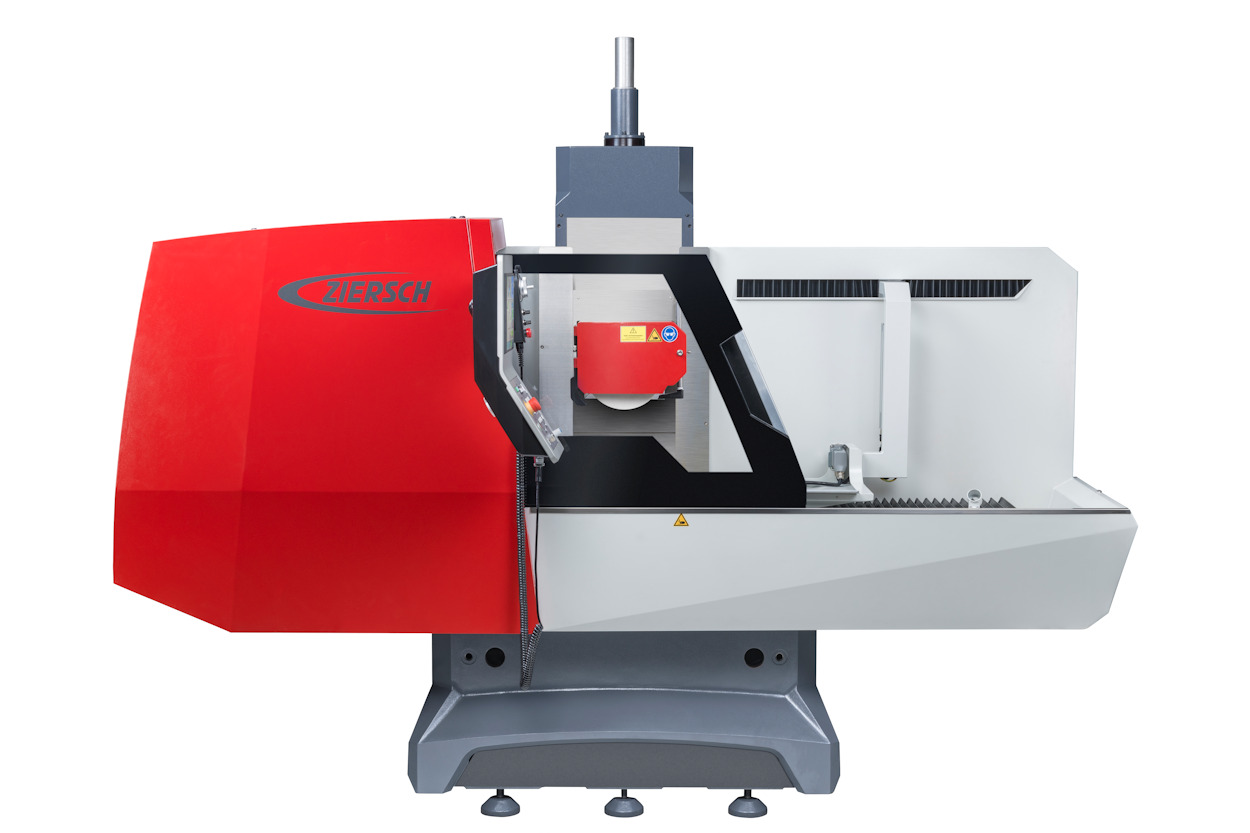

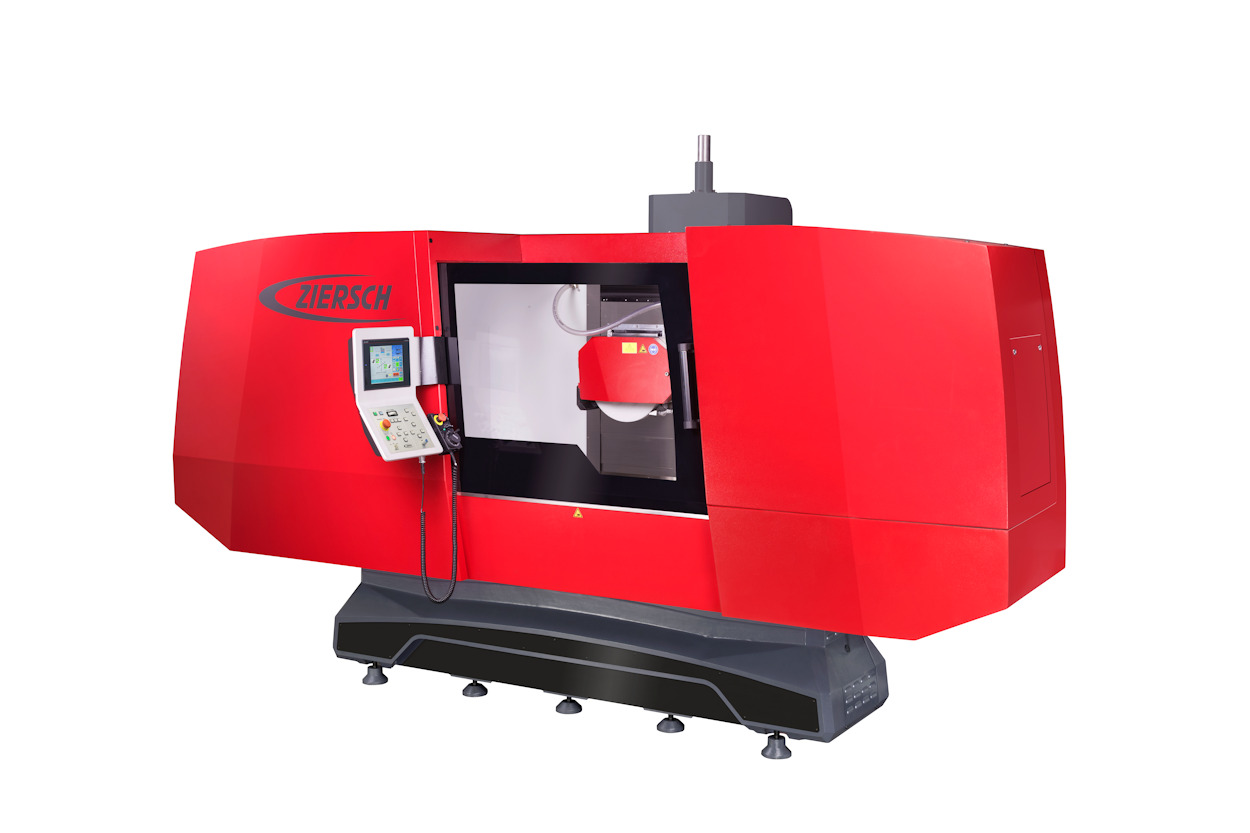

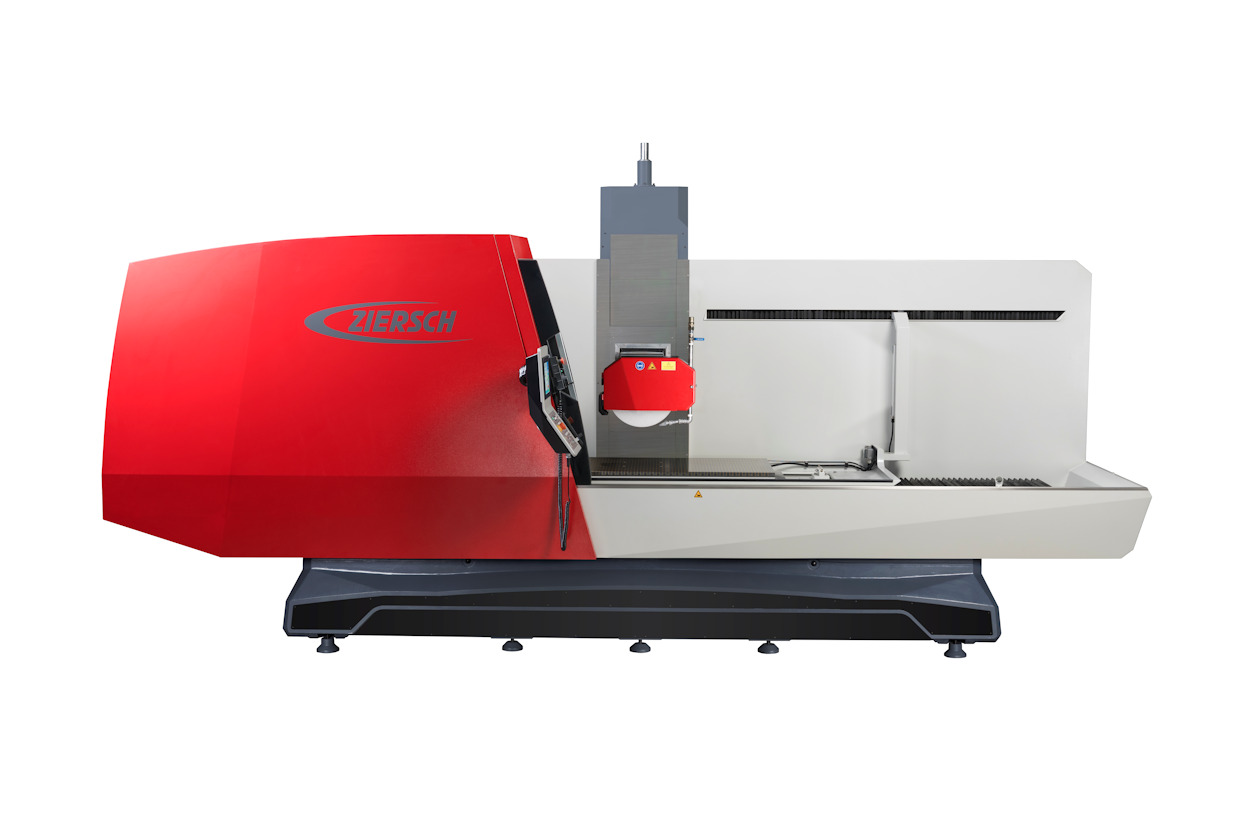

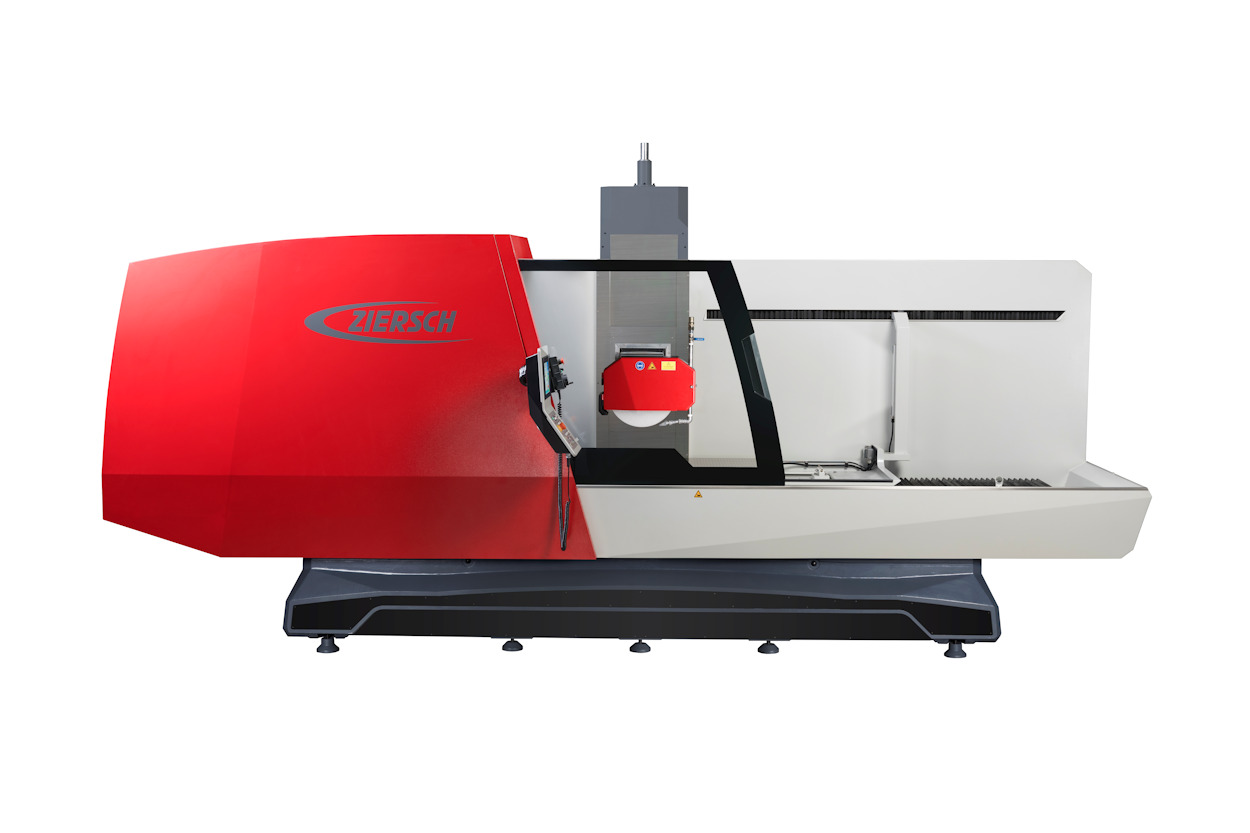

Surface grinding machines Z-SERIES

Features

- Sturdy, cast iron execution of all machine components

- High machine weight for maximum rigidity

- Preloaded precision linear guideways in the vertical- and cross axis (Bosch Rexroth) for highest accuracy

- Scraped and turcite coated slideways in the longitudinal axis provide excellent vibration absorption and a high-quality grinding surface pattern.

- Hydraulic longitudinal motion with return cooling unit to achieve good surfaces

- Electro-mechanic cross- and vertical motion

- Measuring systems in vertical axis (Heidenhain) for precise positioning

- Maintenance-free paper band filtration unit with up to 500 l tank and 2-bar pressure pump for effective cooling and rinsing

- Integrated rinsing channel

- Magnetic separator for prefiltration of the paper band filtration unit

- Infinitely variable grinding spindle motor

- Machine lamp

- Table-mounted dressing device for high precision and surface finish

- Electro-permanent magnetic chuck (SAV) with integrated pole changing unit and traction regulation

- Partial encapsulation of the machine with sliding door and a service door

- Effective splash guard and an excellent accessibility

- Preparation of the machine for installation of a coolant mist exhaust unit

- Very comfortable and easy to operate Z-control

- Automatic vertical infeed with dressing amount compensation

- Fully automatic grinding cycle with dressing cycles

- Easy operation via touchscreen

- Large and clear colour screen (10.4")

- Electronic handwheel, usable in vertical- and cross axis

Z 24

Z 48

Z 612 / Z 715